When someone plans to buy a plot / flat / apartment / row villa / independent villa / duplex house / penthouse, one would typically look at the developer’s reputation, project locality, property approvals, possession readiness, specification, amenities, pricing, discount offers, etc.

Some buyers purchase a property from reputed builders and developers to avoid the hassles and the risks associated with clear title, liaising, and approvals. Some buyers are specific about the project localities they wanted to live in. Some buyers have a constrained budget and therefore, focus on properties within their financial limits. Some buyers want ready-to-move properties for immediate possession. Some buyers invest in properties for long-term gains and for rental yields. Some buyers aspire to live a lavish lifestyle and therefore, seek ultra-luxurious properties.

However, every buyer is curious to know the type of brick used for building construction and which bricks are best for building construction?

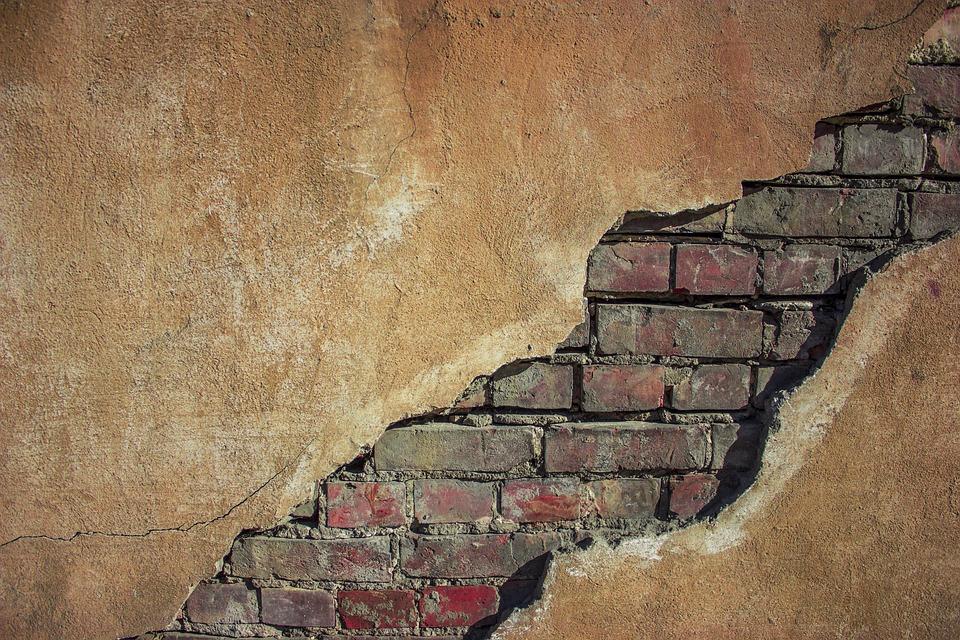

Types of Bricks Used in Building Construction

One gets to hear several types of types – red bricks, fly ash bricks, and concrete blocks. Each type of brick has advantages and disadvantages.

Here’s a blog that gives insight into the specialties of each type of brick.

In primitive days, people used sun-dried bricks. These bricks are made of clay, ground molded, and sun-dried. Even today, these types of bricks are widely used for construction in rural areas. These bricks are highly irregular in shape, less durable, less water-resistant, and less fire-resistant.

Over the period, red bricks became the popular type of brick used for building construction. These bricks are either hand-molded on the ground or on the table or machine-molded and fired in kilns to provide durability and strength to the red bricks. Hence, red bricks have better compressive strength, provide good sound and thermal insulation, are highly fire-resistant, and are easily recyclable. However, the production of red bricks depletes the top fertile soil required for agricultural production and emits carbon dioxide during the firing process causing environmental concerns.

In India, at least 53% of power is generated by burning coal and lignite. Also, Indian coal has a high ash content of 30-45% compared to that of imported coal, which has just 10-15% ash content. India generates at least 220 million tonnes of fly ash every year, which puts an enormous burden on fly ash waste management.

To mitigate dual problems of loss of top fertile soil and carbon dioxide emission during the production of red bricks, the Government of India mandated the use of fly ash bricks that uses fly ash generated from coal-based and lignite-based thermal power plants instead of sand. Compared to red bricks, fly ash bricks are lighter, cheaper, eco-friendly, and uses less mortar. Hence these bricks are widely used in construction-related activities of buildings, roads, flyovers, dams, shoreline protection, etc.

Solid concrete blocks are further classified into fly ash concrete blocks, aerated autoclaved (AAC) blocks, cellular lightweight (CLC) blocks, and paver blocks. Though the cost of solid concrete blocks is higher than that of red bricks and fly ash bricks, the overall cost of construction is lower as solid concrete blocks require less mortar than red bricks.

AAC blocks, also called aerocon bricks, are three times lighter than red bricks and fly ash bricks. These bricks reduce the dead weight of the structure, thereby reducing the consumption of steel and the cost of construction. Hence, AAC blocks are prominently used for high-rise buildings.

Hollow concrete blocks are typically used for boundary wall construction.

For high-rise buildings, some builders also explore aluminium formwork and precast construction technologies to reduce the time for construction and therefore, the cost of construction. These technologies provide the highest carpet area for a given plinth area.

If the locality falls under a medium and high seismic zone, the buildings must be reinforced with concrete and steel. The buildings in earthquake-prone regions prominently use Porotherm seismic clay blocks, which are lightweight and provide excellent bonding with the mortar.

So, which is the best brick for home construction?!

The type of brick that needs to be used depends on the type of building (villa type, medium-rise, or high-rise buildings), locality of the building (seismic or non-seismic zone), cost affordability of the project, and timeline completion. Reputed developers employ the services of renowned architects to design the building and the designs are thoroughly scrutinized by the approving authority.

It’s a dream for many homebuyers to see a building raise up through their eyes. Redbrick is still prevalent for house construction as it remains the preferred choice of building material for many homebuyers.

Staying true to our tagline of concreting your dreams, we at Traventure Homes, are using the best quality red bricks for the ongoing projects. However, the buyers need to be aware that a vast population in India depends on agriculture, which is still the backbone of India. The depletion of top fertile soil required for agricultural production and the emission of carbon dioxide during the manufacturing of red bricks are serious concerns that we share. Also, as the prices of raw materials soar, the usage of red bricks for house construction might become unaffordable. Therefore, we shall have to examine the use of other brick/block types for upcoming projects to support our agriculture production and reduce carbon footprints.